Newton | Engineering and Product Development is assisting the Mars Sample Return mission with a lid built in Fusion 360 utilizing generative design.

Was there life on Mars? It’s one of humanity’s big unanswered puzzles. We might finally get a definitive answer. With the Mars Sample Return Mission, NASA and the European Space Agency (ESA) hope to transport rocks and soil from Mars safely back to Earth for the first time, all with the objective of learning if life ever existed on the planet.

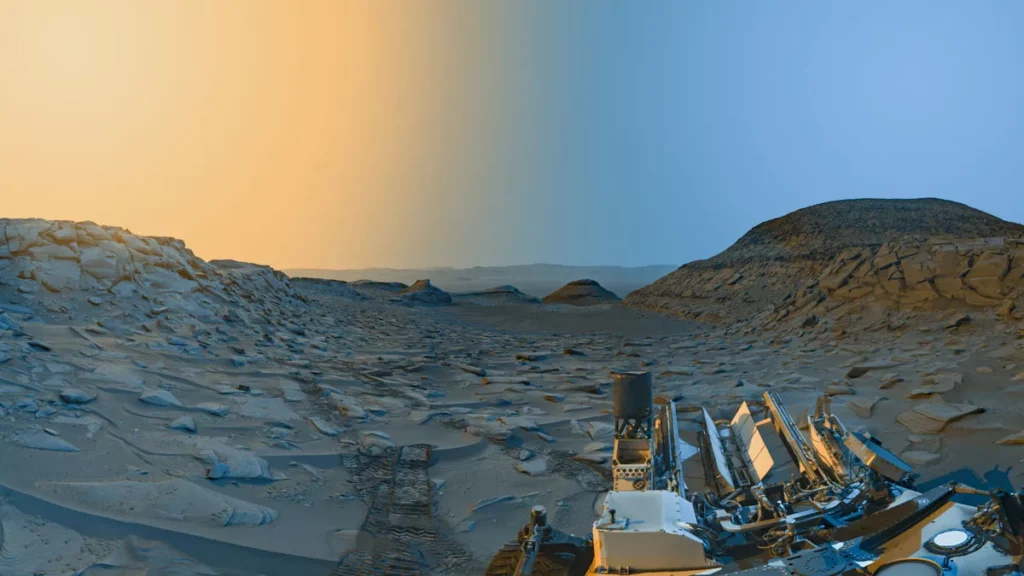

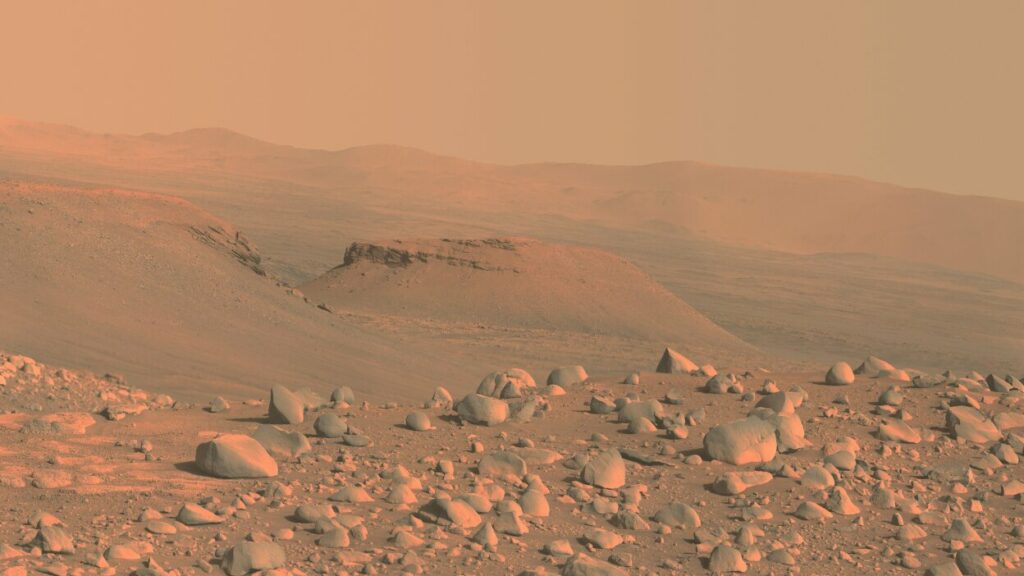

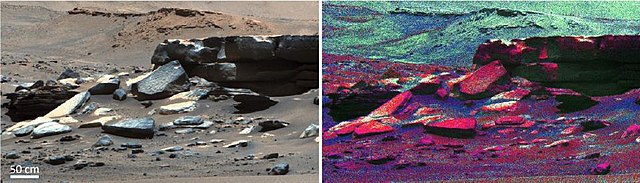

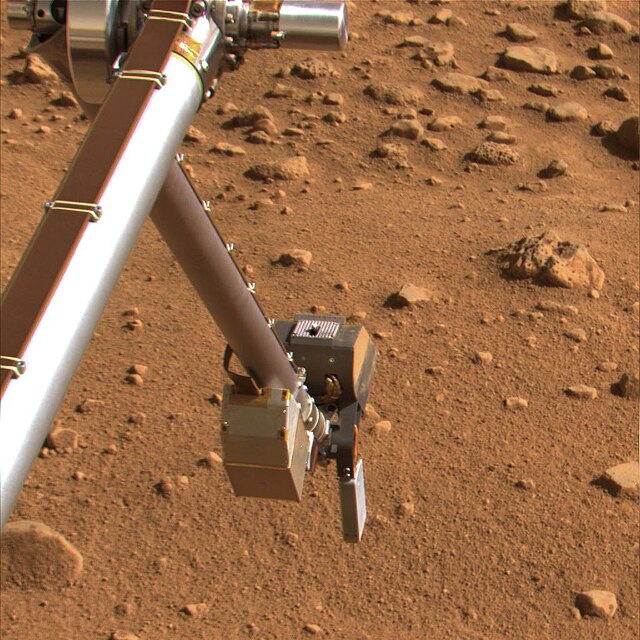

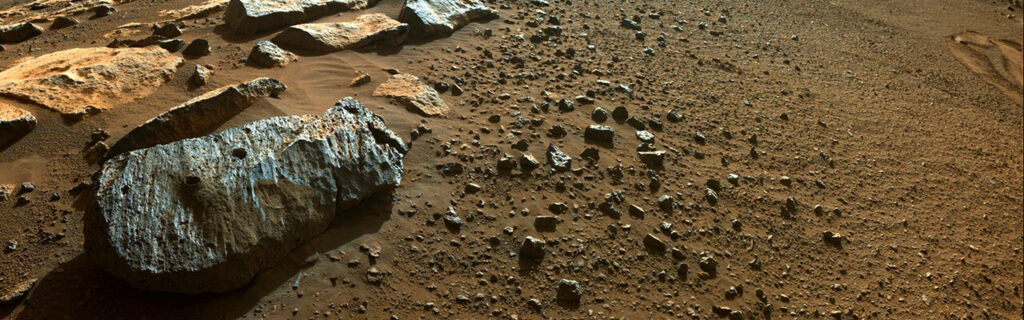

The Mars Perseverance rover is currently on the quest for acceptable materials from several areas in the Jezero Crater delta. Scientists believe a river once flowed into a lake in this area billions of years ago, depositing rocks and sediments, making it an ideal location to seek for ancient signs of life.

Mars Sample Return Procedure

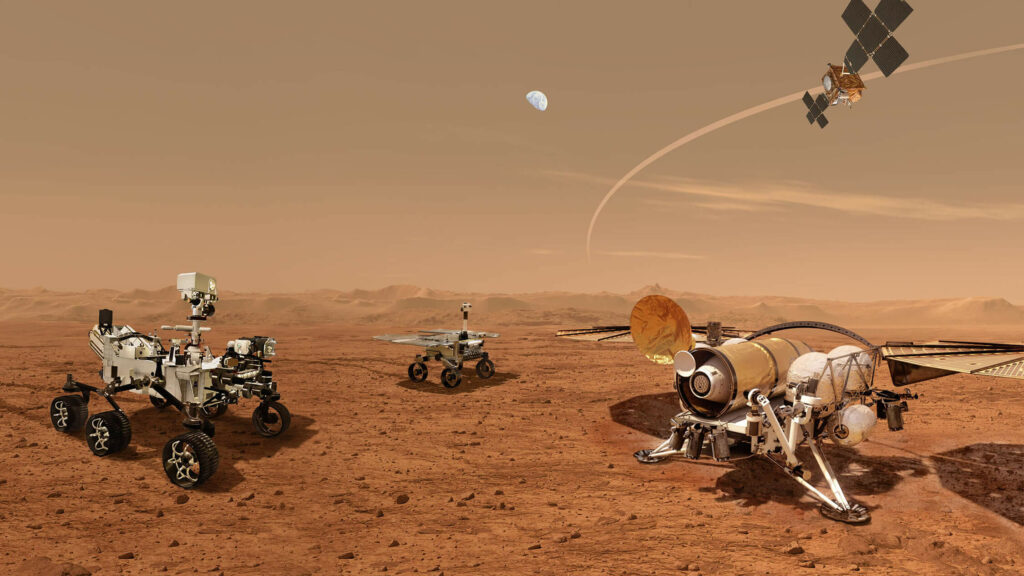

An impressive relay team of equipment, instruments, and technology will be involved in the Mars Sample Return. The samples will be transported in metal tubes by the Perseverance rover to the Sample Retrieval Lander, where they will be placed in the lander’s rocket by an ESA-provided robotic arm. Other samples will be picked up by a pair of helicopters and delivered to the lander.

READ MORE: The Mars Rover Has Produced Enough Oxygen To Last Ten Hours For A Small Dog To Breathe

The priceless payload is then launched into orbit by the Mars Ascent Vehicle, the first rocket to launch from Mars’ surface. It will transport the samples to space, where the Capture, Containment, and Return System on board will capture the samples and sterilize the containers. When the orbiter’s months-long trip return to Earth is nearly complete, an entry vehicle with the rocks will separate from the orbiter and land safely.

As with any scientific activity in space, there are numerous mitigating factors to consider as well as hurdles to overcome in order to make this mission a reality. Everything is now in motion. The lander is scheduled to launch in 2027, followed by the orbiter in 2028. And the expected shipping delivery date to answer our question about life on Mars is 2033. Meanwhile, new ideas and improvements are being developed to ensure that the trip to Mars and return goes off without a hitch.

Keeping the Mars rocks from escaping

Newton | Engineering and Product Development is one of the organizations that is assisting in the development of crucial components for the Mars Sample Return. However, it is not just any part that is being designed; it is a vital component in the transfer of samples from the rocket to the orbiter for the return voyage home.

READ MORE: NASA Has Confined Four People To A Mars Simulator For The Next 378 Days

Each metal sample tube will be “tossed” into the orbiter’s Capture, Containment, and Return System, where it will land precisely in a 3′ long container with a 23″ diameter lid that swiftly snaps shut to protect it from floating away. This door mechanism, known as the Capture Lid Mechanism, is the work of Newton. If it does not open or close, the task will fail

While constructing a lid may appear simple, it is anything but. Many elements must be considered, including contamination restrictions, the speed at which the lid must close, and the need for a simple motor control system.

“There are numerous challenges associated with transferring objects in orbit,” explains Alex Miller, Newton’s chief mechanical engineer. “Once the samples float in, the lid must close quickly to prevent the samples from bouncing out and to limit contamination.” To accomplish this, a door that is both lightweight and sturdy is required. That’s where Fusion 360’s generative design stepped in to aid us with the lid structure.”

READ MORE: A Scientist’s Biggest Fears While Spending A Year On Mars

“We looked at other generative design or topology optimization tools, and none of them could produce ready-to-manufacture parts as easily and quickly as Fusion 360.” Cost is also a consideration. Fusion 360 costs a fraction of what comparable tools do.”

Newton is no stranger to collaboration with NASA. They’ve collaborated on a number of other projects, including the James Webb Space Telescope and the Nancy Grace Roman Space Telescope, to mention a few. However, the Mars Sample Return Mission was the first time Fusion 360 and generative design were used. A research engineer at NASA Goddard Space Flight Center introduced Miller to Fusion 360 about a year ago. The Mars Sample Return mission, according to Miller, is particularly mass-sensitive, and “mass equals cost in the space flight world.”

The team found one component that connects the lid to the rotating hinge and may be mass optimized to increase the torque margin for the movement. It was also necessary to be stiff in order to close the door swiftly. Newton decreased the weight of the lid by 30% using generative design in Fusion 360 while keeping the needed stiffness

Materials were also taken into account during the optimization process. Steel, titanium, aluminum 6061, and aluminum 7075 were all compared. Aluminum was the lightest solution that matched the specifications. Aluminum 6061 was chosen over 7075 because of its improved manufacturability and lower cost while still meeting criteria with more than adequate safety margins.

“We could easily compare the performance of different materials,” said Miller. “we’re able to see the variety of outcomes and how the different material options compared to each other by using generative design in Fusion 360.” We were able to select the best material in a very efficient and timely manner.”

Creating a flight-ready engineering test unit prototype

The team used generative design to continue to develop the design, preserving what was working and flagging other elements to improve. Testing offered additional evidence.

“A lot of people were worried when they saw the generative design for the lid and thought, ‘Oh, those members look thin.'” “Are you certain this isn’t going to break?” Miller asks. “Both our analysis and physical testing showed that it was not going to break and had a higher stress margin when compared to human-made designs.”

Newton is creating the “engineering test unit,” which will precisely match the flying design, after several cycles of testing and improvement. The prototype will be subjected to environmental testing, including vibrations similar to those experienced during launch and several actuations in a Thermal Vacuum chamber that simulates the space environment. It’s an important step in qualifying the design for flight readiness. The lid will be ready for fabrication and delivery to NASA after a second round of testing of the engineering test unit.

READ MORE: For the First Time On Mars, NASA’s Perseverance Rover Captures The Sound Of A Dust Devil

“The biggest advantage with Fusion 360 is that we have confidence knowing what we’re producing is optimal,” Miller said. “It enables us to make effective and efficient engineering decisions.” Using it for the Mars Sample Return saved us roughly a month of time.”

“Given the low cost of Fusion 360 and the ability to produce ready-to-manufacture parts with very little post-processing after the outcomes are generated makes generative design a very effective tool for us.”

Newton is adopting generative design for future projects after the success of the Mars Sample Return. It serves as a wonderful source of inspiration for the team while generating new concepts.

“Fusion 360 is a great tool to quickly generate optimal designs for different concepts early on in the development process,” Miller said. “We can compare ideas and choose the best one to pursue.” It provides us a fair understanding of what’s conceivable and what the parameters would be for each of those diverse concepts.”

Once a proposal has progressed through the design phase, the team might select certain components that they believe will lend themselves well to generative design.

“We can iterate faster than most because of our small teams and the diversity of our engineers’ skills,” Miller said. “Even then, generative design in Fusion 360 has saved us a whole lot of time with weeks and potentially months of development time.”

Miller sees the benefit of adopting generative design becoming more obvious as artificial intelligence (AI) becomes more prevalent.

“I truly believe that humanity is at the dawn of the AI age and using generative design is absolutely essential for any engineering team to remain competitive in the future,” Miller said in a statement. “It’s a critical tool in our mission to provide optimal solutions to customers and ensure success.” Any team or corporation that does not use AI or machine learning tools will quickly lag behind. Our competitive edge stems from our early adoption and finding of efficient methods to use the technology, since I believe it will soon become a common tool for everyone.”

Download The Radiant App To Start Watching!

Web: Watch Now

LGTV™: Download

ROKU™: Download

XBox™: Download

Samsung TV™: Download

Amazon Fire TV™: Download

Android TV™: Download